By Neil Oliver, technical marketing manager, and Michele Windsor, global marketing manager, Accutronics

The Internet of Things (IoT) is about sensor-laden devices in the home and office, but also in industry, medicine and even combat, among other places.

Batteries for Medicine

We are all aware how portable consumer electronic devices have changed our daily lives. It may be a cliché, but it’s a fact that none of these devices would exist were it not for batteries powering them.

Some may shake their heads in disagreement when told that battery technology is keeping pace with technological developments since at first glance it may not seem so. However, even Gordon Moore himself would appreciate the technical challenges associated with providing a large amount of chemical energy in a small space, whilst ensuring it is safe, reliable, cost-effective and reusable.

Despite their technological advancements, it is still challenging to select the right battery to power the load.

In the medical sector, we are seeing ventilators, infusion pumps, dialysis systems and anaesthesia machines move from mains AC power to portable battery power,” said Johnathan Celso, applications engineer at Ultralife. “The increased need for portability in the medical field requires high-discharge batteries that can cope with continuous charge-and-discharge cycles efficiently and safely. This is where new chemistries such as lithium iron phosphate (LiFePO4) are helping us create batteries that improve on traditional sealed lead acid (SLA) technology.

Greater Flexibility

Today, everyone expects portability in the quest for greater flexibility, operability and productivity, and the healthcare sector is no different – we are seeing a massive proliferation of battery-powered portable devices there too.

There are many reasons for equipping an existing medical device with a battery, but the most common is the need to carry it around for use when needed. Portability makes clinicians more efficient and helps prevent moving patients from their beds – the greater flexibility and freedom means better care.

Other medical devices also need batteries, but not necessarily for portability. Patient lifts and acute ventilators are typical examples of transportable medical devices that use batteries and, for these applications, high voltage and discharge rate capabilities are the most important performance attributes.

Here, medical device OEMs are moving away from the older nickel- and lead-based chemistries due to their low energy density and high environmental impact. The focus is now shifting to specialist Lithium-ion (Li-ion) chemistries that have emerged for high drain applications.

Li-ion cathode chemistry that combines nickel, cobalt and manganese offers an enviable combination of performance traits such as capacity, power delivery and safety, making it ideal for demanding applications.

Medical Device Life-Cycle

The rate of technological change in consumer electronics over the past decade is truly staggering. The difference is that the product life cycle of a mobile phone may be twelve to eighteen months, whereas that of medical equipment should exceed ten years.

Although only part of a medical device, the impact of component obsolescence – and in particular of cell supply – can’t be ignored. Until the start of this century, battery manufacturers made cells to defined international mechanical standards, and device manufactures designed their devices around these cells.

The change occurred with the invention of Li-ion and Li-ion polymer cell technology and the new trend of vertically integrating batteries into device manufacturing. This shift has led to the development of customised cells, which in turn has offered medical device manufacturers the option to produce the ideal device for their customers, in accordance with their specifications.

Yet the relentless pursuit of smaller devices means that a cell produced in the millions last year may very well be obsolete and unobtainable next year.

For medical device OEMs this poses a real problem: how to use the latest battery technology and still be able to support devices for 10-15 years.

If early attention is given to possible future developments in cell technology, then it is possible to design a battery platform that can be continually upgraded over the product life-cycle.

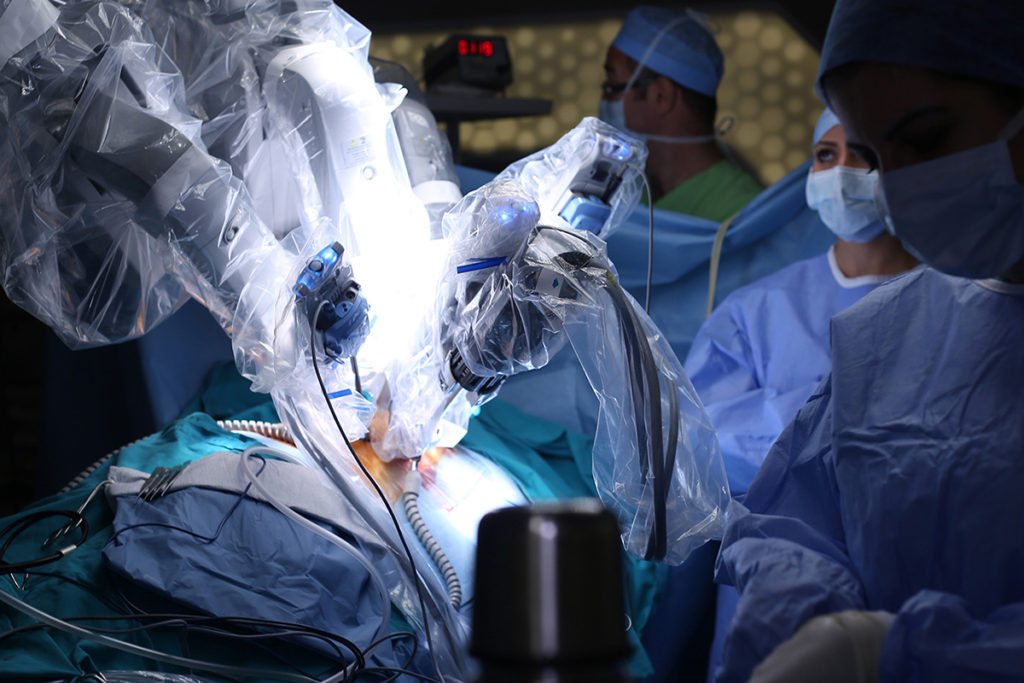

Preparing for The Surgical Robot Boom

With greater investment from healthcare organisations, another discipline benefiting within this field is the surgical robot. The needs here, however, relate to these systems operating safely and reliably.

While they may sometimes feel like a new medical technology, surgical robots have been around for several decades. The first medical robot successfully conducted a neurosurgical biopsy in 1985, while the US Food and Drug Administration (FDA) approved its first surgical robot – the da Vinci – in the year 2000.

However, it’s only in the past few years that we’ve seen this technology really take off.

In the UK, the number of surgical robots used in prostate cancer centres at NHS hospitals tripled between 2010 and 2017. The NHS subsequently invited companies to tender for a £300m surgical robot contract in January 2018, guaranteeing that the number of robot surgeons in the UK continues to grow in the coming years.

This same growth is happening across the world, and the popularity of the da Vinci system is an effective barometer of a growing popularity. According to Intuitive Surgical, the company behind it, the da Vinci robot had sold 4,271 units globally as of September 30, 2017, more than half in the US.

As The Economist reported in 2017, many of Intuitive Surgical’s patents are due to expire soon, leading to greater competition from startups and established companies. This is ideal for the prosperity of the robot market and will help improve the precision and effectiveness of complex, minimally-invasive surgeries. However, it does bring challenges with it.

If new companies enter the surgical robot market, it is critical that their systems are designed to the same quality and safety standards as the ones produced by more-experienced companies. This means that design engineers working on the project must understand the importance of each component in the system, especially critical backup power components such as batteries.

Batteries for Medical Robots

Traditionally, robot systems have used sealed lead acid (SLA) batteries as a backup power source. This is because in hospital environments, with increasingly complex electrical requirements, AC power alone is not always reliable. The critical nature of the application means that even a momentary loss of power can have disastrous, even fatal, consequences.

However, the traditional SLA batteries used in robotic systems have drawbacks. They are bulky and unwieldy, offer relatively low energy density and require maintenance and servicing every two years. When you consider the associated costs, it makes for a relatively high total cost of ownership, which is understandably undesirable in the healthcare sector where a strong return on investment is important.

Fortunately, new movers into the surgical robot market can bypass these traditional problems by designing smart SLA replacement batteries. The role of design engineers in ensuring the safety of the next generation of surgical robots is to consider the proper critical backup power supply early in the process.

By considering alternatives to traditional SLAs, design engineers can design their projects to outperform traditional systems for longer, while maximising patient safety.

How Smart Is Your Battery Charging?

In 1841, the average human life expectancy was 42 years. With significant improvements to medical knowledge and advancements in technology, this has now doubled, and medical device manufacturers are under intense pressures to develop products for the ageing population, at low cost but without compromising quality.

Despite the economic recession and depleting resources, the medical industry has experienced considerable growth since 2011, when the ‘baby boomer’ generation started turning 65, an age when people are becoming more susceptible to disease and disability. The World Health Organisation (WHO) estimates that by 2050 the number of 65-year-olds will significantly outnumber children aged five and under.

All these factors are driving the healthcare system and are a contributing factor to the market growth. In direct response to this increasing need for healthcare, more hospitals are digitising their processes and steering toward a data-driven healthcare system. This also includes more portable medical equipment so that patients can be treated at home to avoid straining hospital resources.

The growing movement toward on-the-go healthcare means that even complex medical devices can now be used away from hospitals and clinics. Although this reduces waiting times and increases the availability of hospital beds, most such devices were not designed for this type of use, leading to a gap between expectation and use.

Poor quality or loss of power are two most prominent issues relating to batteries in healthcare. With portable devices in particular, many original equipment manufacturers (OEMs) struggle to guarantee their mobile devices can perform at the same level as their fixed counterparts.

Accuracy and Reliability

Today, it is fundamental that machines for dialysis or anaesthesia, for example, provide accurate charge status and are highly reliable, with predictable discharge profiles. This is especially important since a power failure in such instances could be fatal.

Another cause of power failure is the actual maintenance of the battery in the application itself. Although doctors from all specialties will be familiar with the use of electronic devices to monitor patient vitals and perform other tasks, most are not aware of how batteries are used within these devices.

For example, remote patient-monitoring machines use backup batteries as a safety measure in the event of a mains power failure.

Many battery problems are the result of inadequate charging methods. Every time a battery is cycled, a small amount of active material is lost. This can be accelerated by deep discharging and rapid charging, which makes predictive maintenance even more challenging. As a result, highly-accurate fuel gauging has never been more important.

Fuel gauges determine the amount of charge remaining in a battery, as well as how much longer it can continue to provide power and efficiently use all its available energy. And since portable devices are designed to be compact, OEMs must also integrate smaller batteries with increased capacity.

Intelligent Charging

As well as looking at the chemistry of a battery, healthcare professionals can ensure workflow efficiency and constant power to devices such as medical carts that allow for a battery hot-swap. Hot-swappable batteries eliminate any power-related downtime whilst ensuring maximum power availability. This is because when using a hot-swappable battery means there is no interruption of power when removing or charging the main power source, offering increased flexibility in low power situations.

Integrating intelligent charging techniques and smart battery electronics can help those working in the medical sector maximise the runtime of their devices. Whether it’s a battery or a charger powering an application like anaesthesia, endoscopy or cardio-pulmonary care machine, doctors no longer need to be afraid of their devices running out of power.